Building Scalable Embedded & IoT Systems

From Prototype to Production: Building Scalable Embedded & IoT Systems

In today’s fast-moving technology landscape, businesses often start with a bold idea—whether it’s a connected medical device, a smart wearable, or an industrial IoT solution. But turning that idea into a reliable, market-ready product is rarely straightforward. Many projects stall between the prototype phase, where proof of concept is demonstrated, and the production stage, where scalability, reliability, and compliance become critical.

At Senologic, we specialize in bridging this gap. With expertise in electronics, firmware, AI, and IoT, we help startups, SMEs, and enterprises move beyond one-off prototypes to create scalable, production-ready embedded systems. In this article, we’ll explore what it takes to move from prototype to production and the key considerations along the way.

Why Prototyping Matters

A prototype is the first tangible form of an idea. It allows teams to:

- Validate concepts quickly

- Test core functionality

- Identify potential risks early

- Gather user feedback

Whether it’s a PCB mock-up, a software demo, or a 3D-printed enclosure, prototypes are meant to fail quickly and improve faster. However, prototypes are rarely optimized for cost, manufacturability, or long-term reliability. This is where many businesses face challenges—getting stuck with a working demo that cannot be scaled efficiently.

The Gap Between Prototype and Production

The shift from prototype to production introduces a new set of requirements:

1. Scalability – Can the design be manufactured at volume without excessive cost or redesign?

2. Reliability – Will the system operate consistently under real-world conditions (temperature, power fluctuations, mechanical stress)?

3. Compliance & Safety – Does the device meet industry standards such as CE, FCC, ISO, or medical certifications?

4. Supply Chain Readiness – Are components chosen with long-term availability in mind, avoiding end-of-life parts?

5. Maintainability – Can firmware be updated remotely (OTA) and hardware serviced when needed?

A proof-of-concept board may work well in the lab, but scaling it for 1,000 or 10,000 units demands a production-focused mindset.

Key Steps in Building Scalable Embedded & IoT Systems

1. Design for Manufacturability (DFM)

Prototypes often use development kits, breakout boards, or easily available components. For production, the design must be optimized for assembly and cost efficiency. This includes:

- Using industry-standard footprints and SMD components

- Reducing BOM (Bill of Materials) complexity

- Ensuring compatibility with automated assembly lines

- Adding test points for quality control

2. Power Efficiency & Reliability

In IoT devices, power management is critical. Battery-powered wearables or sensors must run for months or years without frequent charging or replacement. This requires:

- Low-power microcontrollers (MCUs)

- Smart power regulation (DC-DC converters, sleep modes)

- Careful PCB layout to minimize leakage and noise

Reliability also means robust firmware that can recover from faults and handle unexpected conditions gracefully.

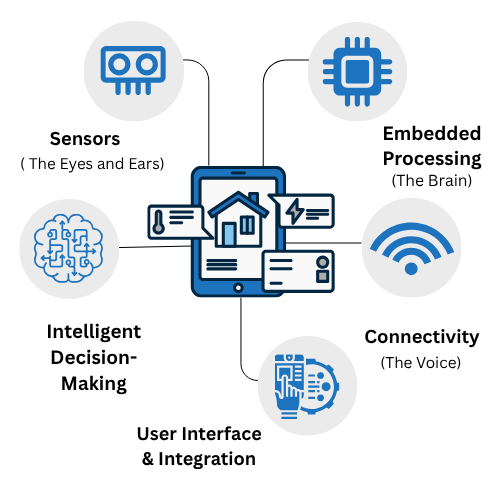

3. Connectivity & Cloud Integration

Scalable IoT systems require secure, reliable connectivity. Depending on the use case, this could involve:

- Wi-Fi or Bluetooth for consumer devices

- LoRa, NB-IoT, or LTE for long-range industrial applications

- Edge AI integration for local decision-making, reducing cloud dependency

Choosing the right communication protocol impacts not only performance but also long-term costs such as data plans and server infrastructure.

4. Security by Design

As devices connect to the internet, cybersecurity becomes non-negotiable. Building secure systems from the ground up involves:

- Encrypted communication (TLS, HTTPS, DTLS)

- Secure boot and firmware authenticity checks

- OTA updates with rollback capability

- Data privacy compliance (GDPR, HIPAA where applicable)

5. Prototyping to Pilot Production

Before going full-scale, a pilot run helps identify manufacturing bottlenecks and design improvements. This stage allows for:

- Field testing with real users

- Fine-tuning performance and durability

- Validating compliance and certification readiness

Common Pitfalls to Avoid

1. Over-engineering early – Adding too many features in the prototype stage often delays production readiness. Focus first on the core value proposition.

2. Ignoring component lifecycle – Choosing parts without considering availability can lead to redesigns when components go obsolete.

3. Skipping security – Security added as an afterthought is costly and often ineffective.

4. Underestimating certification needs – Compliance testing takes time and resources. Planning early prevents delays in market launch.

Real-World Example: Scaling a Smart IoT Device

Imagine a startup building a smart agriculture sensor to monitor soil conditions.

- Prototype Phase: They use an Arduino, Wi-Fi module, and off-the-shelf sensors to prove feasibility.

- Production Preparation: Senologic helps redesign the PCB with an STM32 MCU, low-power LoRa connectivity, and industrial-grade sensors. Power efficiency is optimized, allowing the device to run on a small solar panel.

- Pilot Production: A batch of 100 units is deployed in farms for field validation. Data reliability and connectivity are fine-tuned.

- Mass Production: Once validated, the design is scaled to thousands of units, fully certified and cloud-integrated.

This structured process ensures the idea doesn’t just remain a prototype but becomes a scalable business solution.

How Senologic Helps

At Senologic, we understand both the technical challenges and the business pressures of scaling embedded and IoT systems. Our services include:

- Electronics & PCB Design – Optimized for reliability and manufacturability

- Embedded Firmware Development – Efficient, secure, and maintainable

- AI & Edge Intelligence – Making devices smarter and less cloud-dependent

- IoT Integration – Secure connectivity, cloud dashboards, and mobile apps

- Prototyping to Pilot Runs – Helping clients validate before mass production

Whether you’re a startup with a bold idea or an established company aiming to modernize, Senologic provides end-to-end expertise to take your product from prototype to production.

Final Thoughts

The journey from prototype to production is where most IoT and embedded projects face hurdles. By considering manufacturability, reliability, power efficiency, security, and compliance from the start, businesses can avoid costly redesigns and delays.

At Senologic, we believe that a great idea deserves the chance to become a great product. With the right process and technical expertise, your prototype can evolve into a scalable, production-ready system that makes a real impact.

👉 Ready to turn your prototype into a production-ready product? Book a free consultation with Senologic today.

– The Senologic Team